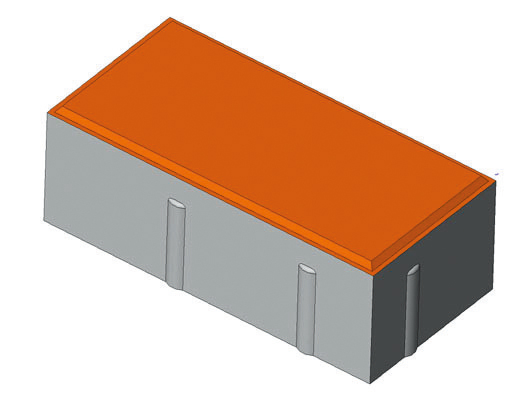

Semi-automatic block machine QT4-40A is one of our sell best block machine model, it is manual operation, suitable for making all types of hollow blocks, solid block, pavers, curbstones and so on. This machine equiped a larger reducer, its key rotary parts are changed into bearings, thickened square steel frame is used and wear resisting material is adopted for its inside sleeves for directional positioning for four guiding columns so that the service life of this machine can be largely prolonged. With the durable quality, stable running, easy operation and cheaper price attract many customers to buy it.

The advantage of our manual Concrete Block Making Machine QT4-40:

Low Cost:

Customers can spend less input cost to buy brick machines for cement brick production.

Easy Operation:

The machine operation is simple, workers can quickly and skillfully operate the equipment.

Convenient Maintenance:

The machine is small and flexible, and can be quickly switched to production when needed.

Good Quality:

According to different profewssional brick laying mould to lay out bricks, neat and thick, high qualification rate.

| Technical Specifications of Semi-automatic block machine QT4-40A | |

| Overall Dimension | 1350x1460x1800mm |

| Main vibration form | Platform vibration |

| Cycle Time | 40-50seconds |

| Vibrating Frequency | 2800-4500 rolls/minute |

| Motors Power | 9.6KW |

| Pallet Size | 860x540mm |

| Brick Raw Materials | crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes. |

| Applied Products | Hollow block, solid bricks, Paving blocks, Curbstone and so on |

| Applied Fields | widely used in buildings, road pavings, squares, gardens, landscaping, city constructions, etc. |

|

Main parameters of Semi-automatic block machine QT4-40A |

|

|

Taille de la palette |

860×540 mm |

|

Pallet maximum forming area |

820×500 mm |

|

Forming Height |

50-200 mm |

|

Durée du cycle |

60-70 Sec |

|

Type of vibration table |

Vibration |

|

Excitation force |

48 KN |

|

Tatol power |

9.6 KW |

| Poids total |

1.8 T |

https://youtube.com/shorts/Vmu_o3QoF54

|

Capacity List of Semi-automatic block machine QT4-40A |

||||

|

Block/ Brick Type |

Picture | Taille | Pcs/Mould |

Pcs/8 hours |

|

Standard brick |

|

240×115×53mm | 26 |

15000 |

|

6 Inch Hollow |

|

400×150×200mm | 5 |

2880 |

|

8 Inch Hollow |

|

400×200×200mm | 4 |

2304 |

| Paving Brick |  |

200×100×60mm | 14 |

7000 |

1.The proportion of aggregates, sand, cement, and the proportion of water in general hollow bricks, 88%:10%:2%, The ratio of raw materials changes according to the strength requirements of the product.

2.The requirement of particles of raw material?

Particles of sand:0—3mm

Particles of stone:1-3mm,,2—5mm,3—8mm & 8—12mm Generally, our stone requirements are within 10mm.

3.How many square meter of factory size required by Simple production line?

Total among 3000-5000㎡,including raw material storage 300-400㎡,main machine 300-400㎡,Curing area 800㎡,finished products 2000m²

4.DJM is a professional high-tech enterprise for concrete block making, owning R&D,

DJM Corporation a été créée au début des années 1990,

qui est située dans la ville de Quanzhou, près du port de Xiamen, en Chine. Depuis plus de 20 ans,

Nous nous développons rapidement et devenons de plus en plus puissants grâce à des innovations technologiques continues et des brevets chinois.

Nos principaux produits sont les suivants : machine à fabriquer des blocs de béton, machine à fabriquer des panneaux isolants composites, ligne de production de briques perméables. Machine à panneaux isolants composites, Ligne de production de briques perméables,

Système de cubage automatique, machine à pavés et à bordures, centrale de mélange et autres machines de construction.

Semi-automatic block machine QT4-40A is one of our sell best block machine model, it is manual operation, suitable for making all types of hollow blocks, solid block, pavers, curbstones and so on. This machine equiped a larger reducer, its key rotary parts are changed into bearings, thickened square steel frame is used and wear resisting material is adopted for its inside sleeves for directional positioning for four guiding columns so that the service life of this machine can be largely prolonged. With the durable quality, stable running, easy operation and cheaper price attract many customers to buy it

Vous avez des questions sur nos produits ?

N'hésitez pas à nous contacter. Les spécialistes produits de DJM sont très heureux de vous aider et de vous fournir des solutions professionnelles et fiables pour vous aider à résoudre divers problèmes.

Devis gratuit

Assurance qualité

Notre société est une entreprise de haute technologie qui intègre la recherche et le développement d'équipements, la fabrication, la vente et le service après-vente.

Copyright © 2024 Quanzhou DJM Equipment Co, Ltd. Tous droits réservés.