A block making machine can produce a wide range of concrete products by changing molds and adjusting raw material ratios, including:

1. Standard concrete blocks

- Solid concrete blocks: used for load-bearing walls, retaining walls, and structural foundations.

- Hollow concrete blocks: lightweight, heat-insulating, suitable for non-load-bearing partition walls and interior wall construction.

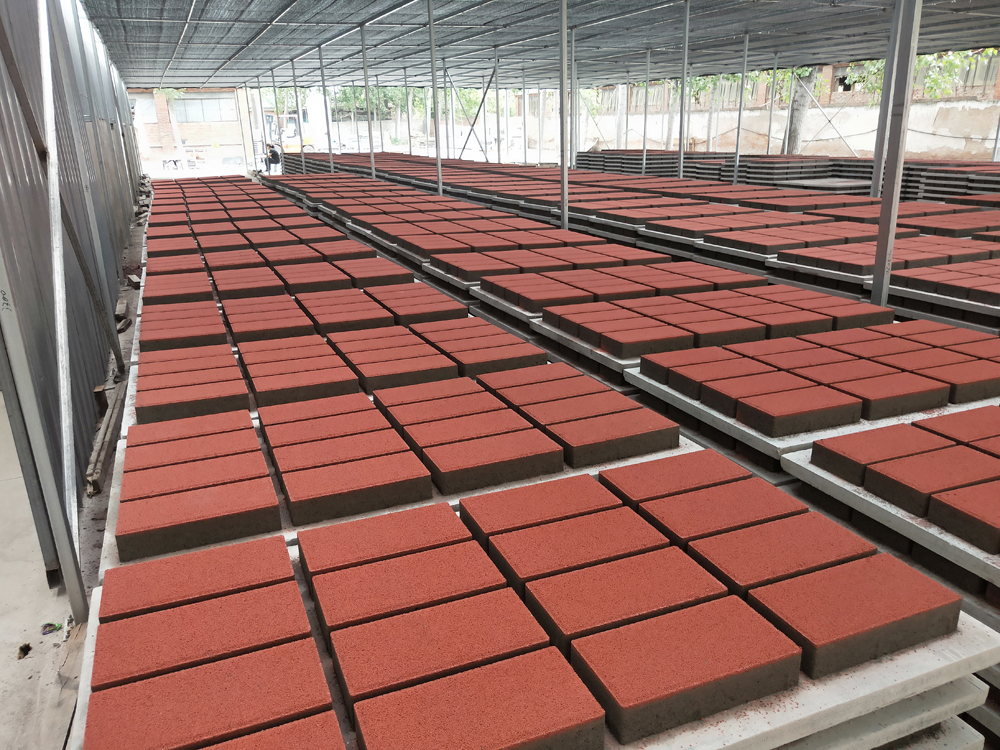

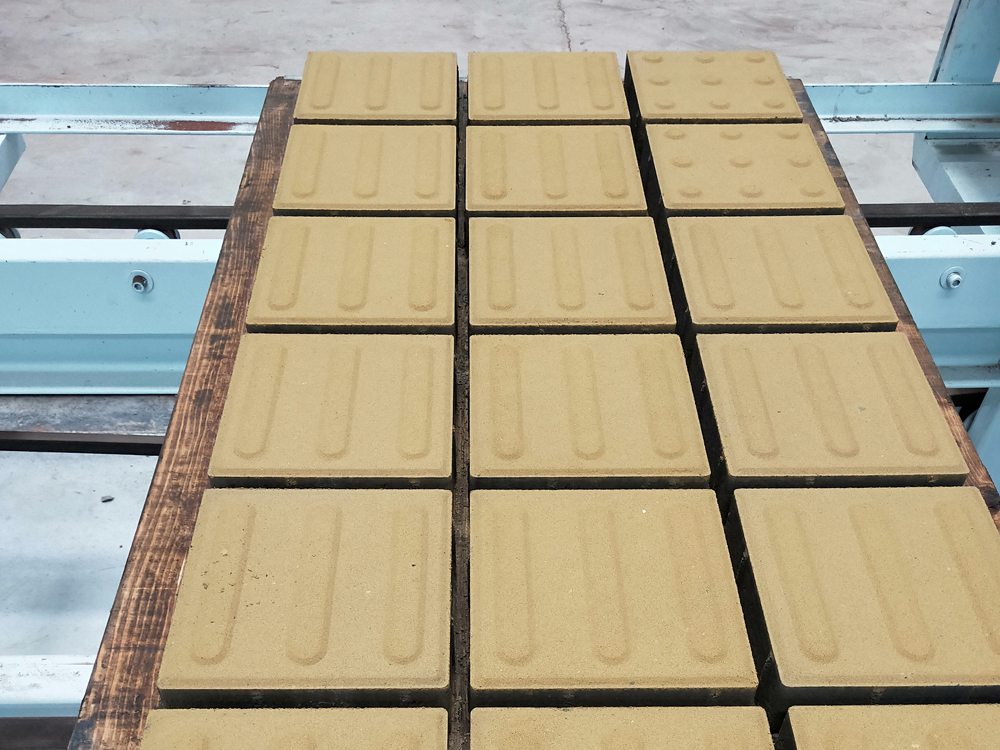

2. Paving products - Interlocking paving stones: applied to sidewalks, parking lots, and plaza ground with good anti-skid and drainage performance.

- Curb stones and kerb stones: used for road edge shaping, separating vehicle lanes and pedestrian areas.

- Grass pavers: porous design, can be filled with soil and grass seeds, for green parking lots and slope protection.

3. Special-shaped concrete components - Concrete bricks: such as perforated bricks, solid bricks, alternative to traditional clay bricks for wall masonry.

- Lintels and small precast beams: used for door and window top load-bearing in small construction projects.

- Manhole covers and drainage channels: customized molds for municipal engineering drainage and pipeline maintenance.

4. Lightweight concrete products - Aerated concrete blocks: mixed with fly ash, perlite and other lightweight aggregates, for high-rise building partition walls with excellent thermal insulation.